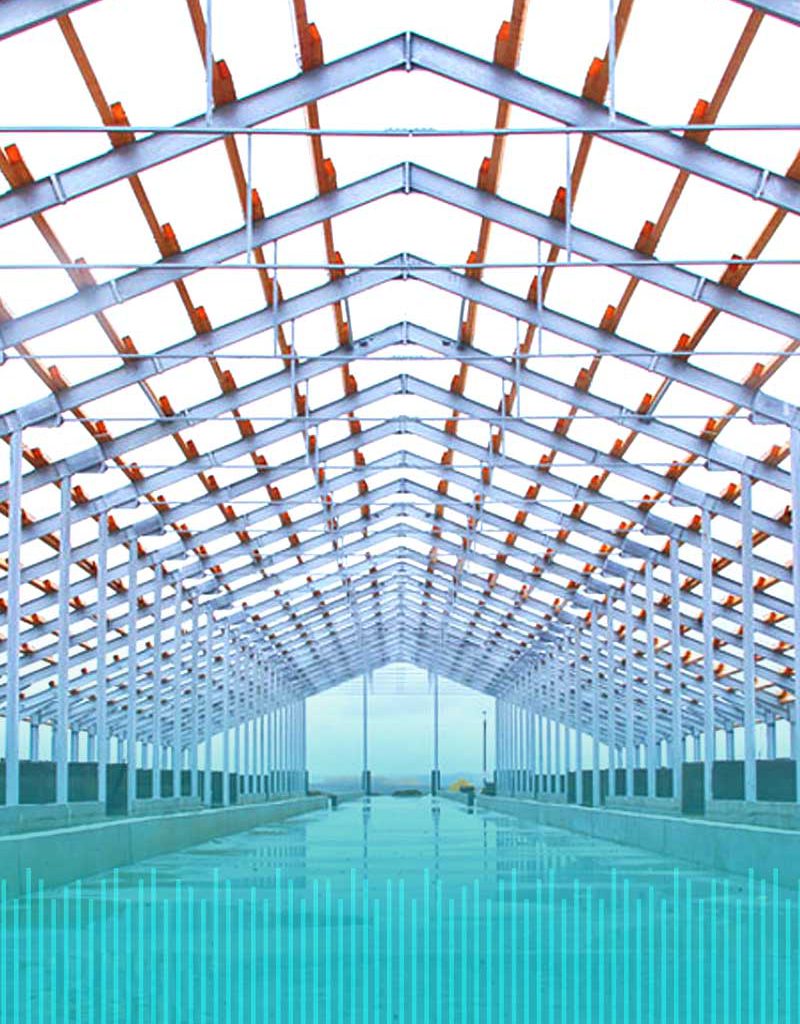

Pre-Engineered Buildings

What is PEB?

A Pre-engineered steel building (PEB) is made of built-up section, hot rolled section and cold formed elements, which are designed and manufactured at our factory and then transported to your site for bolting and erection.

We design your building in a customized way so as to save your cost of civil construction and begin your operations at the earliest.

Projects will be executed on time. construction projects that take 6 months to finish earlier, are reaching completion within 3 months, you get better returns on your capital investment.

Increased customization options: As the demand for unique and customized buildings grows, we offer more options, designs and features to customers.

Future Ready: Can be shifted to other sites due to easy connection of nuts & bolts. Just dismentle the structure and re-assemble at other site.

Complete responsibility and single point solution: No hassles in dealing with different suppliers, contractors, labours, transporters etc. single source responsibility as structural steel engineers, manufactures, supplier and erector.

Cost efficient Space efficient: You can get clear spans to achieve minimum obstruction and your processes can be more easy. You get more space in less cost.

Flexibility: Different combinations of height, coloumn spacing, features, architectural elevation can be done.

One of the biggest advantages in prefabrication structures is that the structures come with fabrication in the plant using high strength and high quality steel.

Engineering has gone through major advancement. Steel concrete composite structures are constructed for e.g high rise building.

Light & Robust: Optimisation of weight and the minimum use of steel without compromising the strength of structure

Greater use of technology: with 3D modelling and virtual reality designing of PEB is more accurate and efficient.

Software driven: Our design department work on latest software and reduce overall project cost and decreases probability of human error.

Energy efficient: Through the use of energy efficient windows, insulation and lighting systems PEB can be designed to be more energy efficient.

Advantages of PEB

Professional Growth

We design, manufacture and erect your steel building as per your exact requirements with required Steel only. That is why it is Pre-Engineered Building and not Pre-Fabricated Shed.

Software-driven

We have our own Design Department with all required softwares. Thus most optimized steel structure design can be given. This reduces overall project cost and decreases probability of human error to negligible.

Light & Robust

Optimization in material consumption is achieved using latest technologies and guidelines. Light weight building is supplied keeping all extreme weather, loads and other conditions in mind.

Flexibility

Because your building is Pre-Engineered, Different combinations of Heights, Column Spacing, Features, and Architectural elevations can be incorporated.

More Space, Less Cost

Get large column-free enclosures to achieve almost zero obstruction in your current processes and all possible future expansions inside the building. That too, without much change in Cost.

Faster Occupation

Total Building is supplied in CKD (Completely Knocked Down) condition; ready to assemble at site. Give faster head-start to your business activities and start getting fruits of your capital investments.

Future Expansion

Steel Shed can be supplied keeping room for future expansion. Just unbolt, disassemble, add new frames, and reassemble. You can save huge costs and time.

Complete Solution & Responsibility

No excuses to you for situations & problems by different suppliers, contractors, labors, or transporters. Single source responsibility as Steel Structural Engineer, Manufacturer, Supplier and Erection.

01. Industrial Applications

Industrial Sheds, Factories, Expansive Warehouses, Workshops, Ginning Mills, Spinning Mills, Foundries, Steel Rolling Mills, Packaging Units, Cement Plants, Industrial Parks, Logistics Parks, Oil Mills, Food Production Units, Cold Storages, Mining and Minerals Processing Plants.

02. Commercial Applications

Showrooms, Distribution Centers, Supermarkets, Large Retail Stores, Restaurants, Office Complexes, Service Stations, Auto Dealership Showrooms, Car Parking Sheds

03 Instutional Applications

Schools, Universities, Exhibition Centers, Hospitals, Theaters, Auditoriums, Sports & Entertainment Arenas, Malls, Stadiums.

04. Aviations & Military Applications

Aircraft Hangars, Airport Terminals, Administration Buildings, Residential Barracks.

05. Agriculture Applications

Greenhouses, Grain Storage, Warehousing.